Nanostructure & Strength Insights #AcademicAchievements

Low-alloyed spring steel undergoes austempering—a heat treatment that changes its microstructure—to improve strength and resilience. In this process, the steel is first austenitized (heated into the austenite phase), then quenched to a temperature above the martensite start, and held isothermally until transformation to bainite or ausferrite occurs. This treatment refines the microstructure, reducing coarse phases and introducing fine bainitic ferrite laths with dispersed high-carbon retained austenite. The result is a steel with increased toughness, higher yield strength, and better fatigue resistance. If you’re interested in recognition or academic validation of work in such steel science, you might explore the opportunities at Academic Achievements and for specific award nominations at Academic Achievements Award Nomination. 🧪🏆 #MaterialsScience #SpringSteel #Austempering #Nanostructure #Strength.

After austempering, low-alloyed spring steel exhibits a nanostructured matrix: bainitic ferrite laths that are only tens of nanometers thick, separated by layers of retained austenite that often are carbon-enriched. Such fine features hinder dislocation motion, raising yield strength, while retained austenite offers a “TRIP” (Transformation Induced Plasticity) effect, enhancing ductility and toughness. Studies demonstrate that steels with lower alloy content (e.g. with small additions of Si, Mn, Cr) can still achieve excellent strength when austempered carefully. For researchers doing work like this, you can get recognition via Academic Achievements and nominate your results at Academic Achievements Award Nomination. 💡 #Nano #Bainite #TRIP #LowAlloy #Strength.

The strength of low-alloyed spring steel after austempering is a function of several factors: the austempering temperature, time held during the isothermal transformation, cooling rates, and prior microstructure (grain size, prior austenite). Lower austempering temperatures tend to generate finer bainitic ferrite laths and higher retained austenite fractions, yielding higher strength but potentially sacrificing some ductility. Conversely, higher austempering temperatures give coarser microstructure with more ductility but lower strength. For validation of such findings, consider Academic Achievements and submitting nomination via Academic Achievements Award Nomination to showcase your contribution. ⚙️ #HeatTreatment #AustemperingTemp #MaterialsEngineering #Balance #Strength.

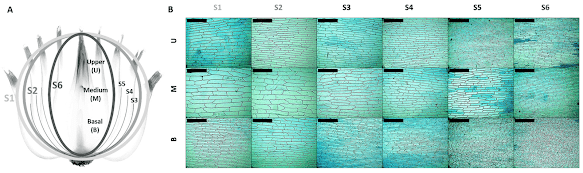

Microstructure characterization techniques—such as transmission electron microscopy (TEM), scanning electron microscopy (SEM), X-ray diffraction (XRD), and even atom probe tomography—reveal the nanostructure of austempered steels. TEM highlights the ferrite laths’ thickness and their spacing; XRD can quantify retained austenite content and carbon enrichment; atom probe tomography can even map local chemistry within the phases. Such detailed characterization underpins understanding of how austempering conditions affect mechanical behavior. If you want your work acknowledged in these advanced materials studies, check out Academic Achievements and nominate using Academic Achievements Award Nomination. 🔍 #Characterization #XRD #TEM #Microstructure #Innovation.

Mechanical testing reveals that austempered low-alloy spring steels can attain yield strengths well above conventional quenched and tempered versions, while also maintaining fatigue limits and impact toughness. For example, steels treated at moderate austempering temperatures may reach tensile strengths of ~1 200-1 400 MPa with good elongation, whereas traditional treatments may offer lower combinations. The fine bainitic microstructure with retained austenite aids in crack blunting and delays crack propagation. Publishing such data, you could leverage Academic Achievements, and for recognition nominate via Academic Achievements Award Nomination. 🏋️♂️ #MechanicalProperties #TensileStrength #Fatigue #ImpactToughness #HighPerformance.

Beyond strength, austempered low-alloy spring steel shows excellent fatigue resistance, especially under cyclic loading, and better wear behavior. The nanostructured bainitic ferrite and stabilized retained austenite mitigate initiation sites for fatigue cracks. Moreover, in applications like springs, suspension components, and other cyclic service parts, these improved properties can lead to longer service life and reduced maintenance. To disseminate your findings or get industry attention, consider Academic Achievements and the nomination process at Academic Achievements Award Nomination. 🔧 #Fatigue #Wear #ServiceLife #AppliedMaterials #Engineering.

However, there are trade-offs. Extremely fine microstructures may suffer from instability of retained austenite under very high stress or temperature, possibly converting to martensite prematurely and causing brittleness. Also, lower alloy content means limited hardenability, making the process sensitive to section size, cooling uniformity, and processing control. The cost of processing (holding times, precise temperature control) can be higher, potentially affecting industrial scalability. If you overcome such challenges in your research, it’s worth sharing via Academic Achievements and nominating your achievement at Academic Achievements Award Nomination. ⚠️ #TradeOffs #Instability #ProcessingChallenges #ScaleUp #MaterialsDesign.

Recent research trends include optimizing alloying additions to balance strength, toughness, and cost; exploring lower austempering temperatures combined with ultrafine prior austenite grain sizes; engineering multi-phase nanostructures; and using computational modeling to predict microstructure outcomes. Another exciting area is additive manufacturing followed by austempering, enabling complex spring components with tailored microstructures. If your work pushes these boundaries, don’t forget to highlight it through Academic Achievements and nominate via Academic Achievements Award Nomination. 🌱 #ResearchFrontier #Modeling #AdditiveManufacturing #UltraFine #NextGenSteel.

In conclusion, austempering presents a powerful path for low-alloyed spring steel to attain outstanding combinations of strength, toughness, fatigue resistance, and service performance via a refined nanostructure of bainitic ferrite and carbon-rich retained austenite. The interplay of austempering parameters, alloy chemistry, prior microstructure, and processing control determines the final properties. As the field progresses, consistent characterization, validation, and recognition of work become increasingly important. If you are reporting novel data in this domain, you should share your findings via Academic Achievements and secure recognition by nominating at Academic Achievements Award Nomination. 🚀 #Summary #Future #MaterialsScience #Steel #Austempering.

https://academicachievements.org/

https://academicachievements.org/award-nomination/?ecategory=Awards&rcategory=Awardee

support@academicachivements.org

Get Connected Here:

Facebook : https://www.facebook.com/profile.php?id=100092743040677

Whatsapp: https://whatsapp.com/channel/0029Vb4zVNL8F2pFjvhPYC3H

Twitter : https://x.com/VineetaSingh28

Instagram : https://www.instagram.com/academic.achievements19/

Comments

Post a Comment